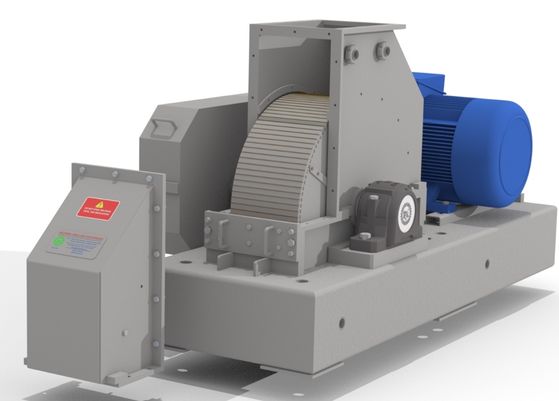

Starch / Sago industries that need Rasper has:

Food-grade hygiene

Maximum throughput

Minimum wastage

Modern Sheller’s Rasper cater to all these important requirements of industry:

Manufactured in all-food-grade SS304 stainless steel

Manufactured in all-food-grade SS304 stainless steel Extraction of more starch

Extraction of more starch Powerful motor drive

Powerful motor drive

Designed with:

- A large rotor diameter with grooves

- The reversible rotor of the rasping blade increases the life of the blade

- A more efficient screen plate and clamping bar design is adopted,

- Efficacy of milling at its highest

- The device is easy to replace, service and maintain

Efficient processing:

High speed of rotation

High speed of rotation The rasper is easy to operate, easy to maintain,

and accessible.

The rasper is easy to operate, easy to maintain,

and accessible.

Other features:

- The rasper is easy to operate, easy to maintain,

and accessible. - The device is easy to replace, service and maintain

- Clamping the blades are both firm and solid

- Using a reversible rotor extends the life of saw blades