Process Flow

No two requirements are the same. We thoroughly analyze the client’s requirements and propose the solution, instead of one-equipment-fits-all approach. We assess the risks of the existing system and evaluate a solution which removes the risks totally while at the same time works in a sustained manner, enabling the client to improve his business. A logical flow is devised from one equipment to another and we either do a total turnkey solution from receipt of raw materials to the delivery of the finished product or we create solutions specific to a component of the client’s existing setup. The components of the proposed solution are then designed to create an engineering model, taking into consideration the strength of materials, the wear and tear expected and the space available at the client’s premises. Trial runs of the proposed solution are then conducted and it is thoroughly tested before commissioning. Each and every step is documented in a detailed manner, allowing for smooth upscaling at a later stage, if so desired.

Modernisation and improved operational efficiency

The client, a leading brand and a major producer of food products in India, was using extensive manpower for day-to-day activities. Blending of different grades of grains and packaging them for sale was time-consuming. It was labour-intensive and productivity was low.

Learn More

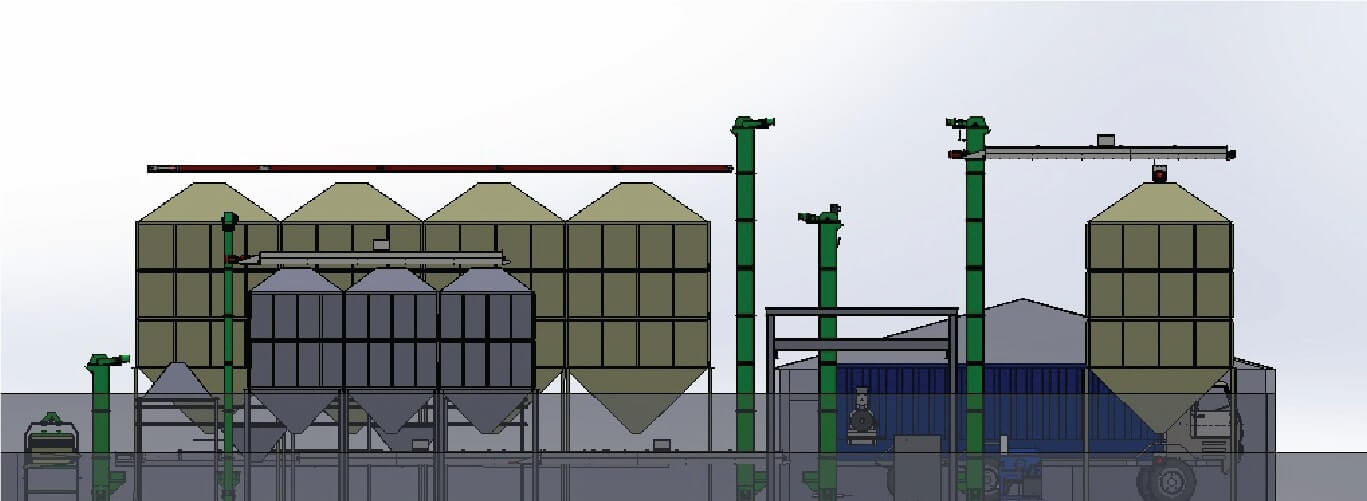

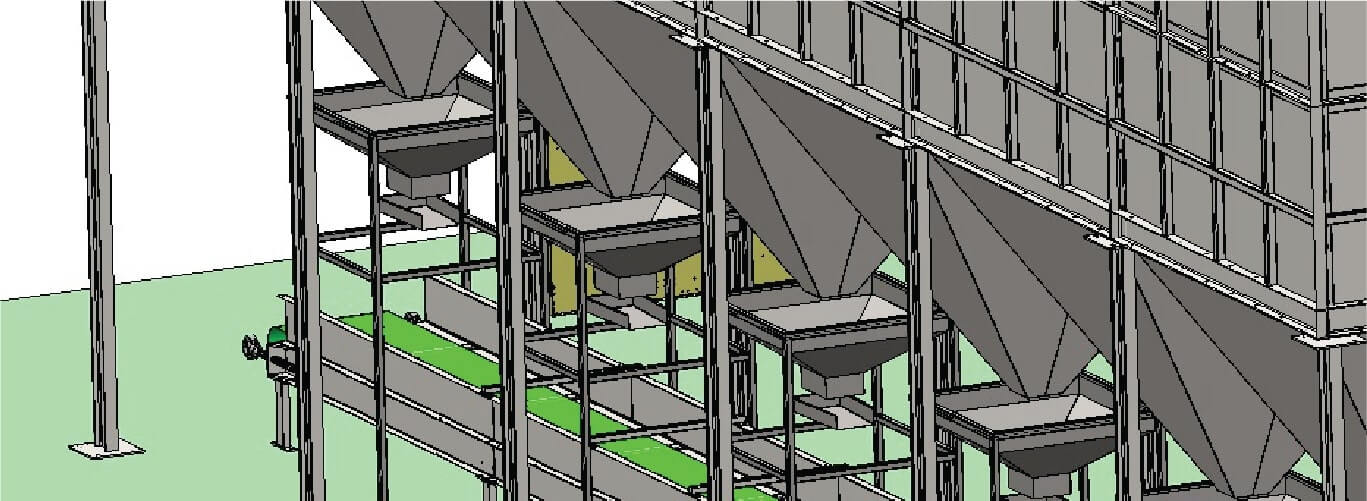

Top-of-the-line Storage and Material Handling

One of the leading brands in beverages required a high volume storage with seamless production process. The processing of raw material from plantation to the final dispatch involves various stages such as storage, sorting, blending, and roasting.

Learn More

Automation for smooth portfolio expansion

A long-standing beverage company wanted to expand its product portfolio with the help of automation to sustain the quality savoured by their customers. The process automation needed to happen seamlessly with the customers enjoying the same brand value.

Learn More