How We Work

Our team is composed of multi-disciplinary professionals with years of experience and our management team has handled numerous projects, making us the company-of-choice for innovation and quality. With advanced design and data communication systems, we are well equipped with a modern workshop comprising lathes, radial drilling machines, plate rolling machines, arc welding machines, tig welding machines, plasma cutting machine, hydraulic press, shearing machine and a 5T EOT crane.

Each project is not just an equipment sale, but the equipment is a part of a larger solution we offer to our client. We constantly innovate to produce the latest equipment range, thus ensuring that our clients receive nothing but the best from us. Our range is exhaustive for the food processing undustry and each equipment leaves our premises only after the most stringent quality checks. Our emphasis is on the best materials to be used for each equipment, such as SS304 steel and galvanised steel. What’s more, we offer customised solutions after a thorough understanding of needs.

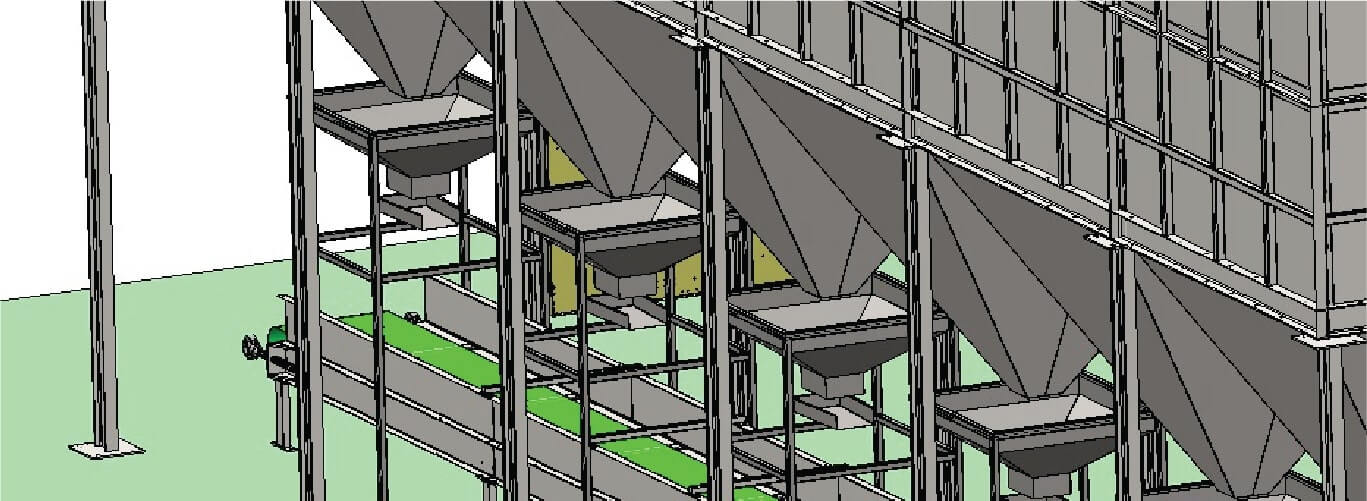

Modernisation and improved operational efficiency

The client, a leading brand and a major producer of food products in India, was using extensive manpower for day-to-day activities. Blending of different grades of grains and packaging them for sale was time-consuming. It was labour-intensive and productivity was low.

Learn More

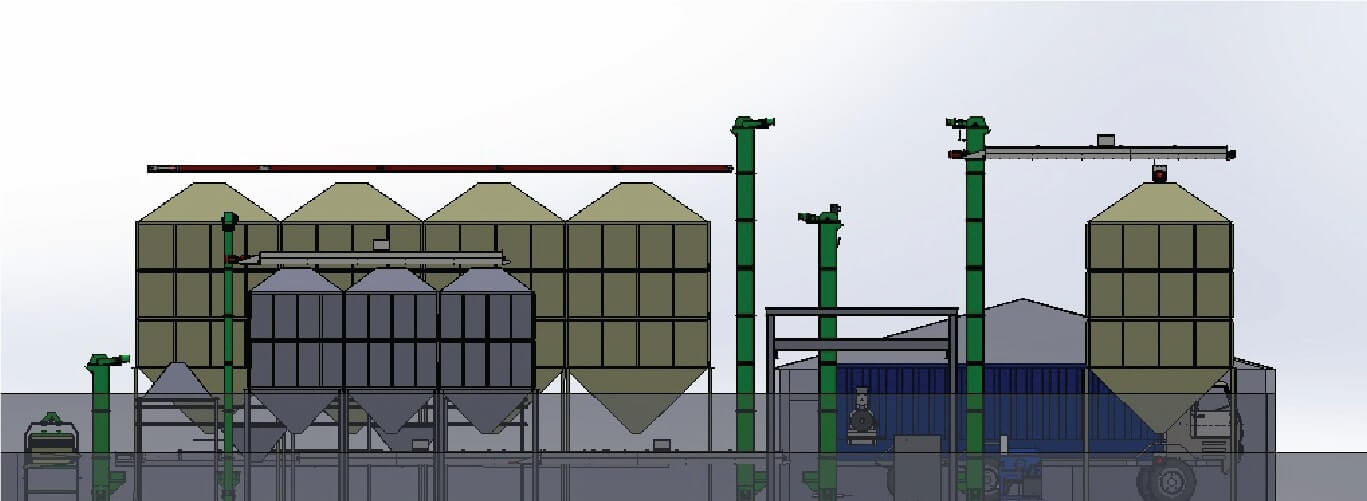

Top-of-the-line Storage and Material Handling

One of the leading brands in beverages required a high volume storage with seamless production process. The processing of raw material from plantation to the final dispatch involves various stages such as storage, sorting, blending, and roasting.

Learn More

Automation for smooth portfolio expansion

A long-standing beverage company wanted to expand its product portfolio with the help of automation to sustain the quality savoured by their customers. The process automation needed to happen seamlessly with the customers enjoying the same brand value.

Learn More