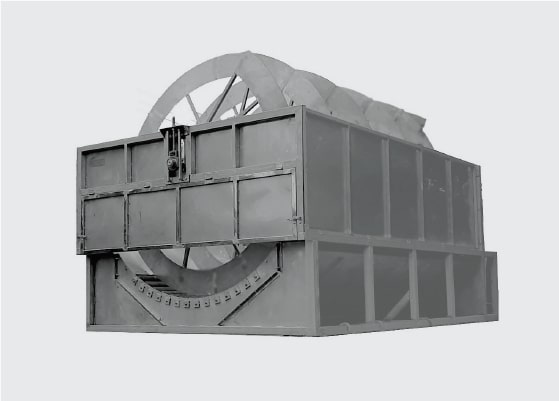

Food processing industries that need vegetable peeling look for:

Easy to clean equipment to maintain food-grade hygiene

Lower wastage to reduce cost of raw material

High reliability to reduce downtime

Modern Sheller’s Peeling Machine cater to all these important requirements of industry:

Manufactured using food-grade SS304 stainless steel, making them rust-free and easy to clean, thus maintaining food-grade hygienic conditions

Manufactured using food-grade SS304 stainless steel, making them rust-free and easy to clean, thus maintaining food-grade hygienic conditions Designed with minimal gap between the rollers to ensure fine peeling and low wastage of pulp, ensuring peeling rate of over 95%

Designed with minimal gap between the rollers to ensure fine peeling and low wastage of pulp, ensuring peeling rate of over 95%Constructed to last:

- Use of SS304 ensures longer life for the machine as a whole.

- The design of roller shafts are made for easy replacement ensuring lower production down-time.

- The rollers are driven by high-precision belts for better reliability

Other features:

Wide range to suit every throughput need

Wide range to suit every throughput need Customisable screw diameters, roller diameters, roller length to suit every application

Customisable screw diameters, roller diameters, roller length to suit every application

- Adjustable motors

- Maintenance-free

- Extremely robust, capable of non-stop operation for 24 hours

- User-friendly