Automation for smooth portfolio expansion

A long-standing beverage company wanted to expand its product portfolio with the help of automation to sustain the quality savoured by their customers. The process automation needed to happen seamlessly with the customers enjoying the same brand value.

Project Scope

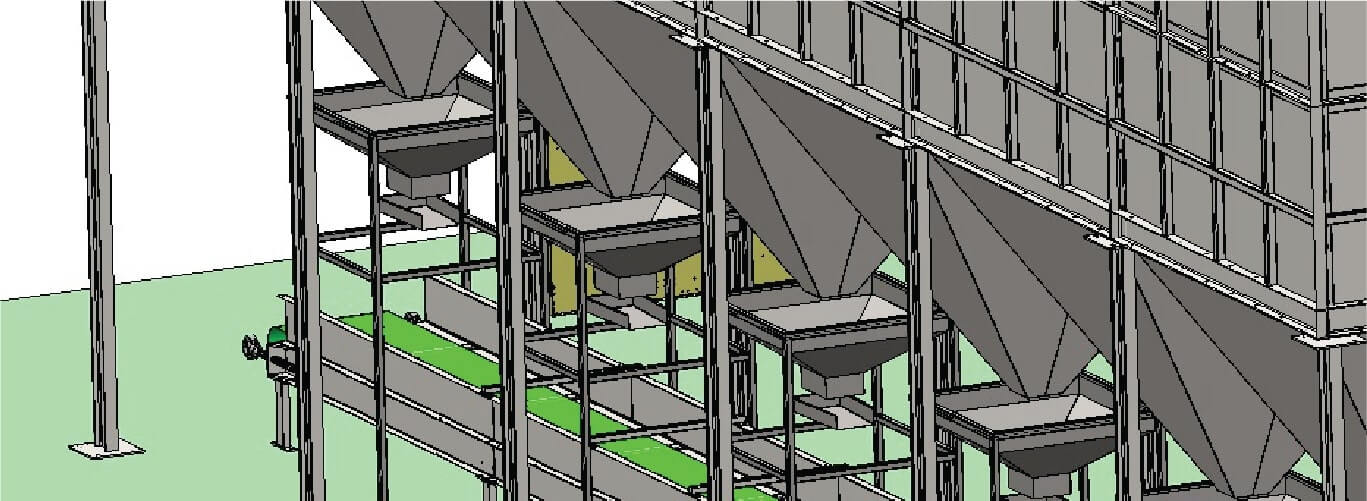

Our customer required a fully automated blending system for different grades of raw material in order to sustain high quality and uniform standardised product to their customers. Modern Sheller Industries proposed a PLC & SCADA-based complete automation system enabling seamless operations.

Solution

Our complete PLC automation solution for blending of raw material is programmable. Each of the 16 hoppers, fitted with programmable electronic controls, is selected dynamically for each raw material. The programmable mix-and-match produces an array of blends, enabling the brand to offer more variety without compromising on quality. The roasted raw-materials are loaded into the corresponding hopper through the belt conveyor. The weight of the filling hopper is displayed in the load-cell. After the loading is completed, the operation is switched for loading the other raw materials. Once the required composition is available in the corresponding hoppers, blending is turned ON. Just a single click selection of the product name and the quantity discharges the raw materials uniformly by opening the pneumatic sliding gates and the vibratory system fitted at the outlet(s) of the hopper(s). This is done in a controlled manner by varying the vibration speed based on the weight in the load-cell. The requisite materials for the final blending of a suitable composition reaches the blender where the final

blending takes place. The final product is bagged at the other end of the belt conveyor by a single manpower. The entire system is automated with PLC & SCADA.

Benefits

The automation resulted in quality enhancement. Workforce was reduced considerably with the increase in productivity. Customer satisfaction was increased by offering the same best standard, time-after-time.